장비안내

Si BEOL & GaN MPW

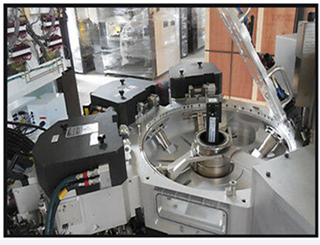

- 장비아이디 FS-PE10

- 장비명 HDP-CVD(고밀도플라즈마 화학기상증착기)

- Model Centura5200 Ultima/DxZ

- Maker APPLIED MATERIALS

- 담당자 박성민

- 연락처 031-546-6232

- E-Mail sungmin.park@kanc.re.kr

- 상 태 ● (가동중)

적용가능한 기판 정보

O (가능) / △ (협의필요) / X (불가능)

| 기판 종류 | 기판 Size | 기판 Type | 기판 두께 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | III-V | Glass | Flex | 조각 | 2" | 4" | 6" | 8" | 12" | 플랫 | 노치 | Normal | Special |

| O | X | X | X | X | X | X | X | O | X | △ | O | O | X |

장비사양(Hardware Specification)

General Information

ㆍ Wafer Specification

- Wafer Size : 200mm

- Wafer Shape : SNNF (Semi Notch No Flat)

ㆍ Platform Type : Centura 5200 (HDP Ultima + DxZ)

- HDP Process Chamber

- Dxz Process Chamber

- Multi slot Cool-down Chamber

- Oriental Chamber

- Left/Right Load-lock Chamber

공정성능(Process Specification)

ㆍ Process : IMD Deposition (USG)

- Dep-Etch-Dep Method

- Deposition thickness : up to 2㎛

- Wafer Temperature : 370~500℃

- Deposition Rate : 4000±400A/min

- Refractive Index : 1.460±0.01 (@ THK:1000A, 파장: 632nm)

- Gap-fill : Pattern Wafer Void Free

- Uniformity <±5% (within wafer thickness(@49 points, EE 5mm) & wafer-to-wafer (@ 5wafers)

ㆍ Process : IMD Deposition (FSG)

- Dep Rate : 3000±300A/min

- Sputter Rate : 1300±200A/min

- Film Uniformity : ≤ ±5%

(within wafer thickness(@41 points, EE 5mm) & wafer-to-wafer (@ 5wafers)

- Refractive Index : 1.44±0.01 (@ THK:1000A, 파장: 632nm)

- Gap-fill : Pattern Wafer Void Free

- F concentration : 4.0±1.0wt%(@ Film THK:6000A)

활용분야(Application)

ㆍ Insulator Layer Deposition for semiconductor

- IMD(Inter Metal Dielectric Deposition (FSG & USG)

- Passivation Deposition (SiO2 & Nitride)